Previous

Entry Top Next

Entry

10/26/2004 - Interfacing the Motors, Sensors & Soil

Sampler to the OOPic II

Overview

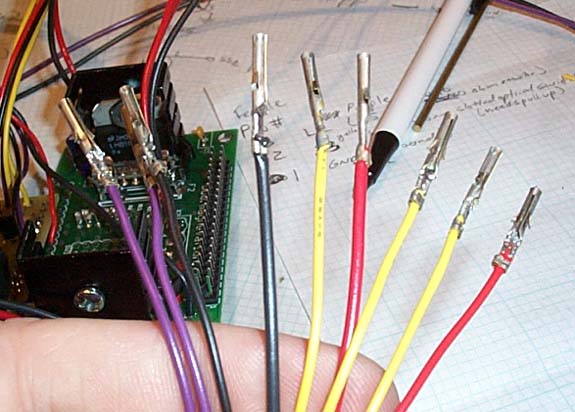

Photo showing the completed interface for the Leg Section

The

nine wires coming from each Motor as well as the Soil Sampler

must be interfaced to the OOPics.

This

involves two circuit boards, one purchased off the shelf and another

which I designed and had produced for me.

The

first is the Magnevation

Dual PMW Driver Board which I purchased. This printed

circuit board (PCB) allows the OOPic to control two DC motors.

It has inputs for ground and the motor voltage (24vDC in

my case) and outputs two wires for each motor. It is made

to work with the OOPic and the two are connected together via

their 40 pin connectors using a short ribbon cable.

Our

other 7 wires (S1, S2, S3, L1, L2, +5vDC, GND) feed out of a custom

designed PCB which I created using the service provided by www.ExpressPCB.com

This Encoder Interface Board (EIB) provides a spot for the resistors

and transistors needed to allow the OOPic to power (L1, L2, GND,

+5vDC) and read the Encoder outputs (S1, S2) and the optical switch

output (S3).

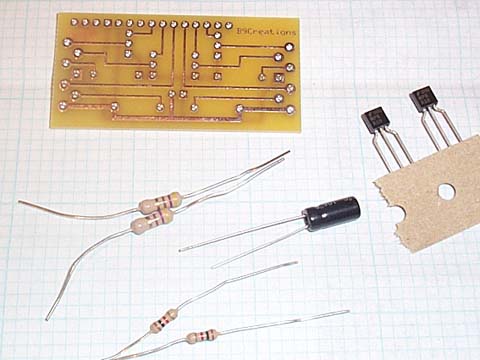

Here's

a photo of my Encoder Interface Board with components:

Here

are the EIB's circuit diagram and the board layout files. Note

that you'll need the free ExpressPCB

software to open these!

EIB

Circuit Diagram

EIB Board

Layout

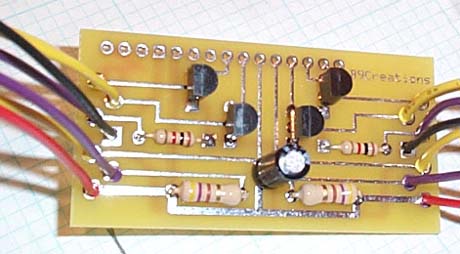

Here's

a shot of the EIB after build up:

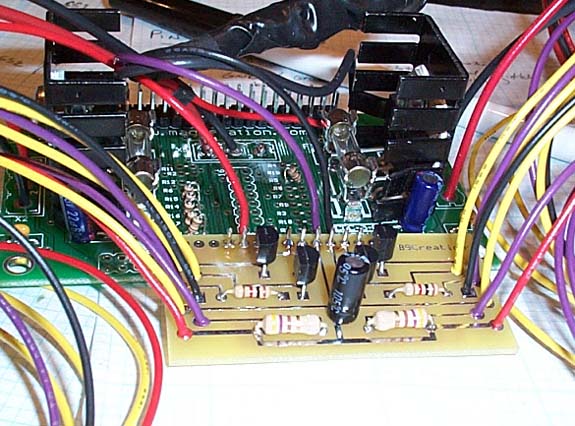

And

Here it is attached to the Magnevation Dual PWM board.

Molex

terminals crimped and soldered.

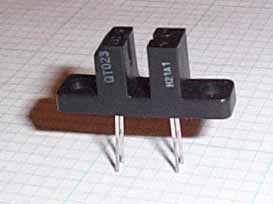

Optical

Switches

I'm

using a H21A1/2/3 Slotted Optical switch. This

device has four pins (1-4). Pins 2&4 go to Ground, Pin

1 connects to L1 & Pin 3 is the output which connects to S3.

Here's the data sheet

for this switch (pdf). These can be purchased from

DigiKey. (DigiKey part #

H21A1-ND, $1.08 each)

Between

the EIB and the Magnevation Dual PWM we have completely interfaced

both of the 9-pin motor connectors (both the Hip Actuator motor

and the Torso Rotation motor).

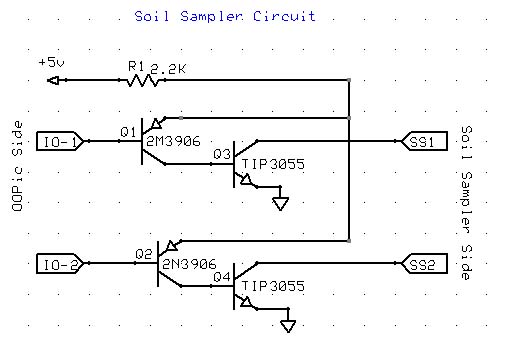

Soil

Sampler Control

That

leaves the Soil Sampler interface as the last responsibility of

the leg section OOPic.

I

had planned to use relays but decided it would be best if I could

come up with a solid state circuit that the OOPic could use to

control the Soil Sampler.

I also wanted to be able to stop the Soil Sampler in mid-motion

when the Power Pack is pulled. So I bring both the

SS's ground supply wire and it's trigger wire up to the OOPic

using a two wire cable. Black(SS1) is the SS's ground

line (cut this and everything stops, ie Power Pack pulled). Purple(SS2)

is the SS's Trigger line (hold this to ground for about three

seconds to start the cycle).

I

didn't make a PCB for this. Instead I soldered everything together

in-line and used wire shrink tube to protect it. Basically

there are two circuits, SS1 & SS2, each of which can connect

it's output line to ground under OOPic Control. The

OOPic will control the Soil Sampler by grounding SS1 (cycle power)

for 20 seconds (long enough to cycle) and SS2 (trigger ground)

for about three seconds. If the power pack is pulled then

SS1 can be opened and the Soil Sampler will stop moving until

SS2 is closed again (Power pack plugged back in).

I

used some transistors from Radio Shack to construct the solid

state relays.

Here's the

circuit I used:

(Click

here to Download the ExpressPCB Circuit File)

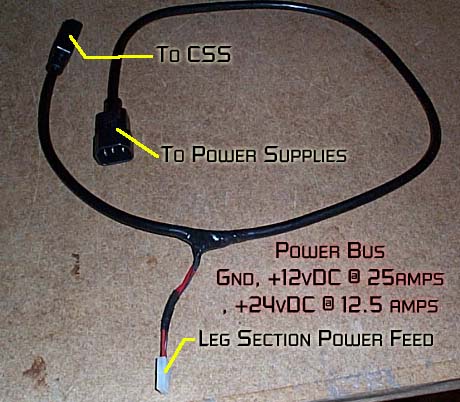

Power

Bus and OOPic Power connections

I'm

using 16 gauge AC power cords to bus DC power through the Robot.

They are readily available, flexible, and can be purchased

with connectors on each end.

The

ones I am using are three wire conductors. I'm using Green

as Ground, Blue as 12vDC and Brown as 24vDC. A patch cord

with a sliced in feed for the leg section circuits is used in

the leg section:

OOPic

I/O Line Usage

Every

sensor(input) and every output from the OOPic needs a dedicated

I/O line. Here's a list of the I/O lines used and their

connection.

I/O

Line 1: SS1 - Active Low Output. Connects the Soil

Sampler's Ground line.

I/O Line 2: SS2 - Active Low Output. Triggers the Soil Sampler

cycle when held low for three seconds.

I/O

Lines 18, 24 & 26 - PWM outputs for motor 1 (Hip actuator).

I/O

Lines 17, 25 & 27 - PWM outputs for motor 2 (Torso Rotation).

I/O

Lines 15 & 14- Motor 1 (hip) Encoder inputs (S1, S2).

I/O Lines 13 Motor 1 (hip) Optical switch input (S3)

I/O

Lines 10 & 11- Motor 2 (torso) Encoder inputs (S1, S2).

I/O Lines 12 Motor 2 (torso) Optical switch input (S3)

Previous

Entry Top Next

Entry