Previous

Entry Top Next

Entry

10/29/2004 - Building the Donut Assembly

The

Donut, lazy susan and waist plate form a single assembly. There's

an optical switch and interuptor plate also attached, it is used

to determine the straight ahead position.

First,

we drill out and tap eight 5/16" holes in the outer ring

of the lazy susan. The outer ring will be stationary and the inner

ring will turn. Eight 3.5" long support rods are

cut from 5/16"-18 threaded rod stock.

The

inner ring gets six 1/4"-20 holes drilled out and tapped.

Use the six counter sunk holes already present (the counter

sunk side is the bottom).

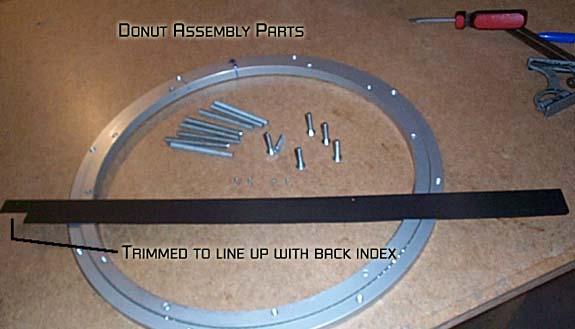

Cut

a strip to act as the interupter for the optical switch from 1/16

aluminum sheet.

Use

clamps to hold the strip in place, it should be flush with the

top of the lazy susan.

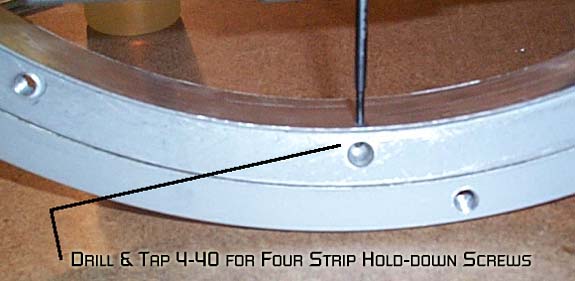

Bottom

view:

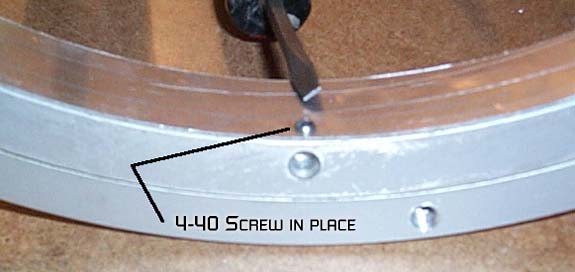

Drill

and tap 4-40 screws. Note how these line up with the unused pre-drilled

holes.

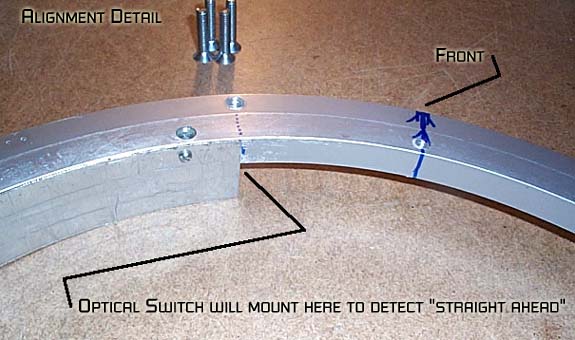

The

alignment is critical. The leading edge of the interuptor should

line up with the support post as in this photo.

After it's mounted trim the trailing edge to be exactly 180 degrees

offset. Paint it flat black to reduce reflections that might

cause false signals.

Here

are all the fabricated parts prior to assembly

Lazy

Susan assembly complete: Top View

Bottom

View

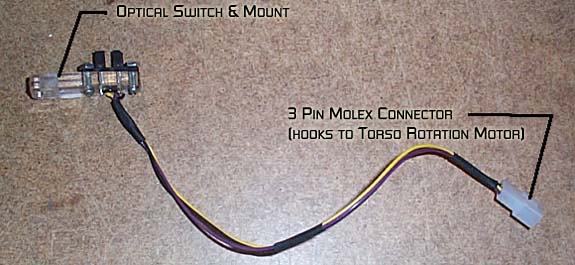

Here's

the optical switch with a fabricated mount made from a 1/4"

piece of acrylic.

Here's

a shot of how the switch interacts with the strip.

Here's

the donut with 8 hole drilled to allow the 8 threaded rods to

pass through it. Also, 8 screws are in place to act as spacers

to raise the lazy susan to the correct height.

Here's

the waistplate with 8 holes drilled for the support rods. Note

the counter bored holes to allow for nuts that are flush with

the bottom of the waist plate.

Lazy

susan in place in the dount.

Waist

Plate in position, held there by nuts on the threaded rods.

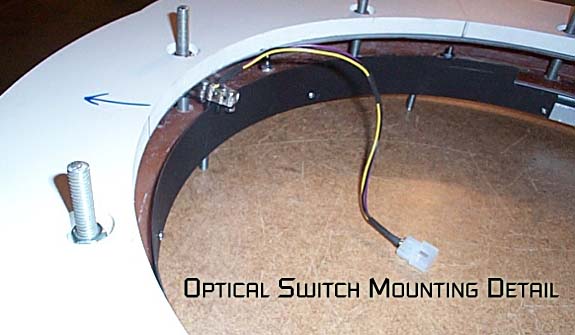

Optical

Switch Mounts on threaded rod.

Central

Support Structure (CSS) bottom plate. Fabricated from 1/8 aluminum

plate.

Drill

the torso to match the CSS plate.

Make

sure the torso rotates without binding. There should be about

1/16" clearance between the torso and the donut.

That's

it for now!

Previous

Entry Top Next

Entry