B9 Robot Building Through The Years

Strap in and click below

2017

03/24/2017

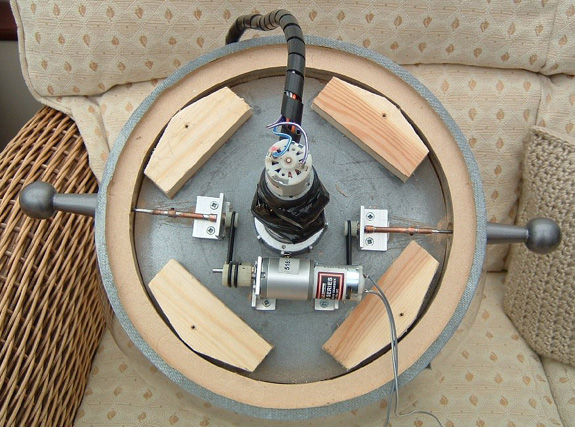

My neck from Will Huff, I made the inner rings for it on my CNC machine.

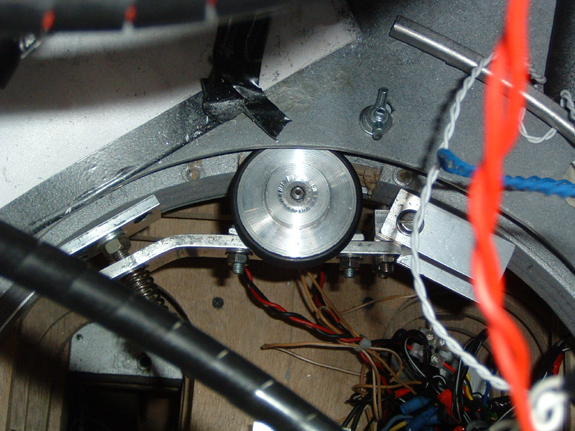

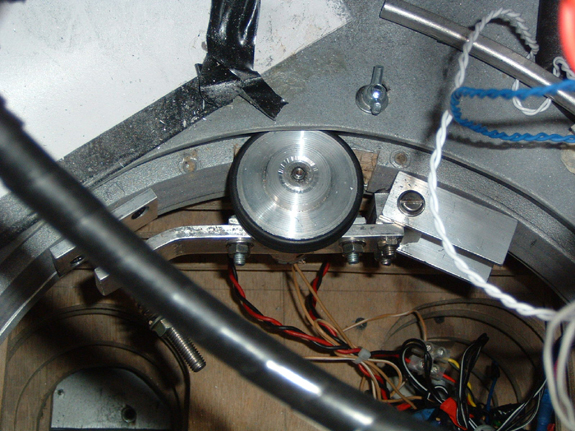

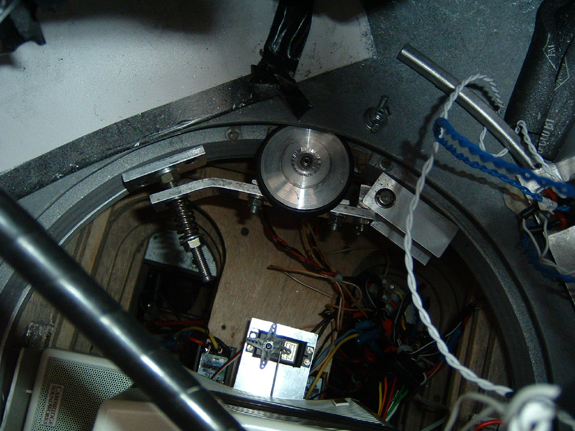

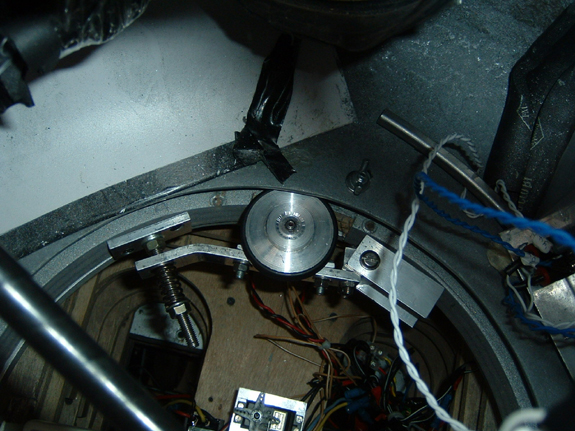

The brain motor was inserted into the neck pipe to reduce motor vibration & noise.

I added some extra padding in the neck pipe and the motor is silent now.

Neck pipe was spare waste pipe & fittings I had from a plumbing job at home.

The neck is fixed but can easily be modified for movement if required later.

Here are some pictures:

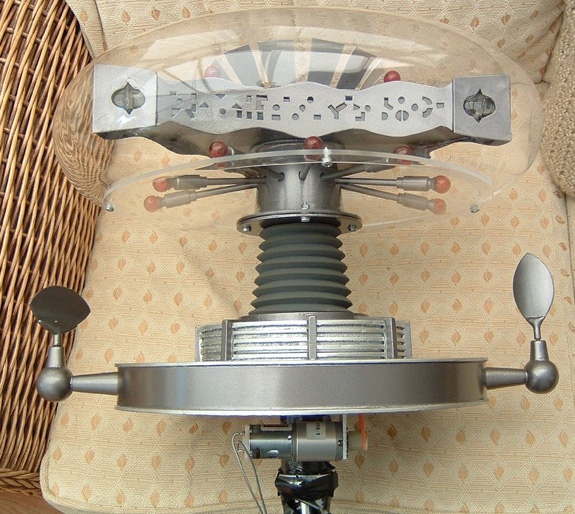

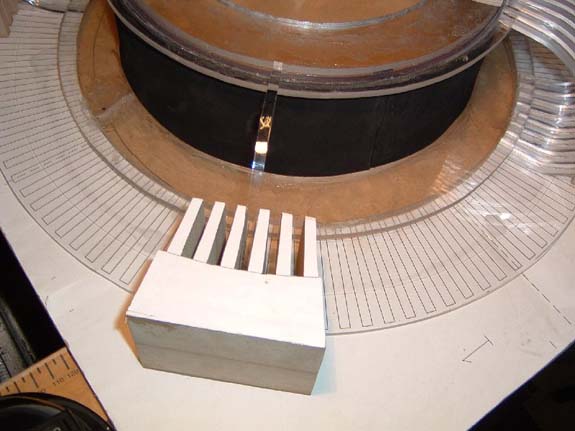

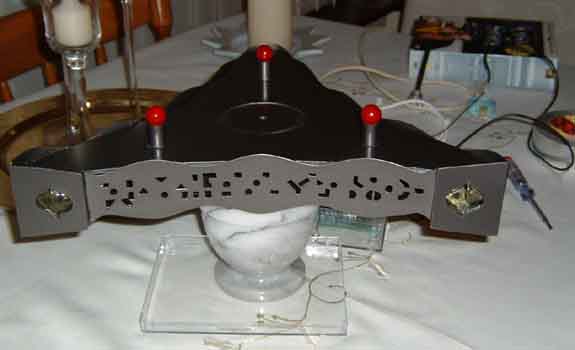

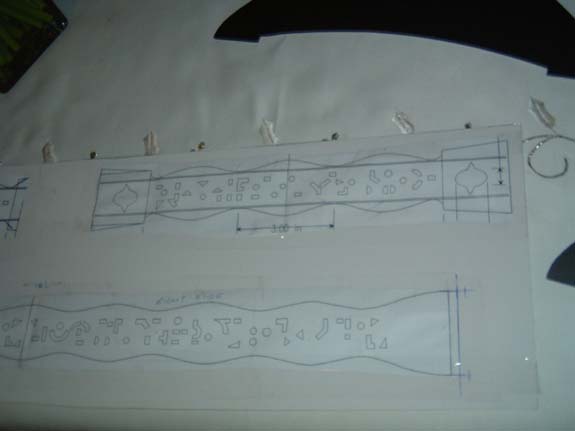

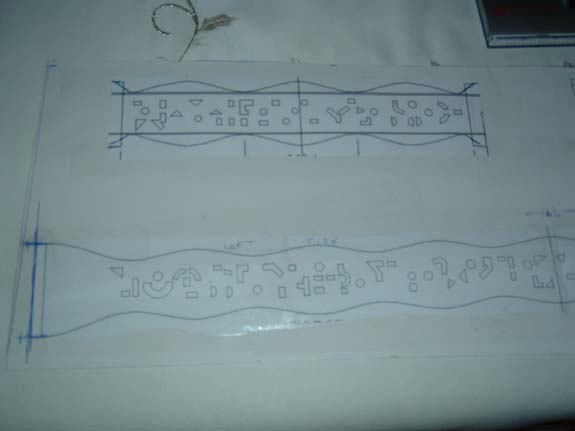

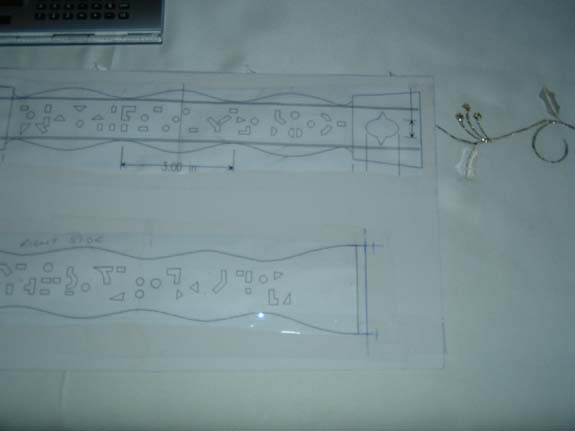

I made my 2nd radar from acrylic, using the blueprints from the club website & the reference material, plus my old one as a template.

The Radar is laser cut Acrylic , the DT department at the School where Julie works really like my B9.

To save time, they let me use their laser cutting machine instead of me machining the parts using my CNC.

The top radar ring that is at the base of the neck was made on my CNC. It took a while but was the exact correct size.

The large rings would have been too big for my machine & the large middle bit was made at my friends machine shop on a very large Lathe.

Here are some pictures:

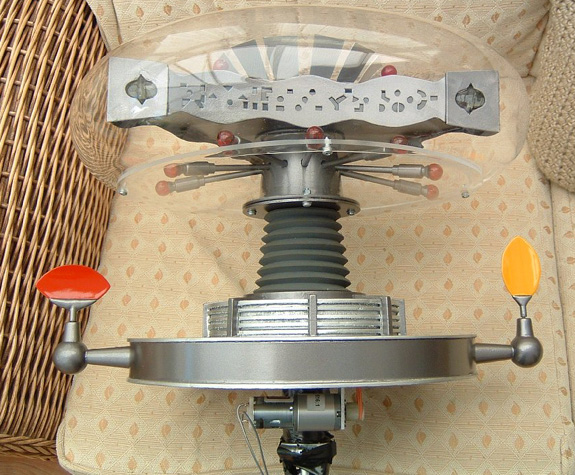

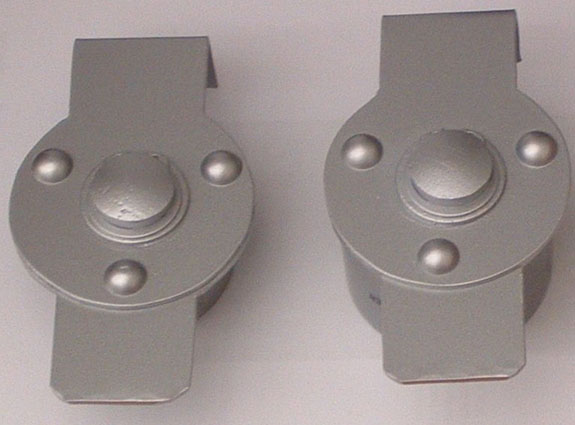

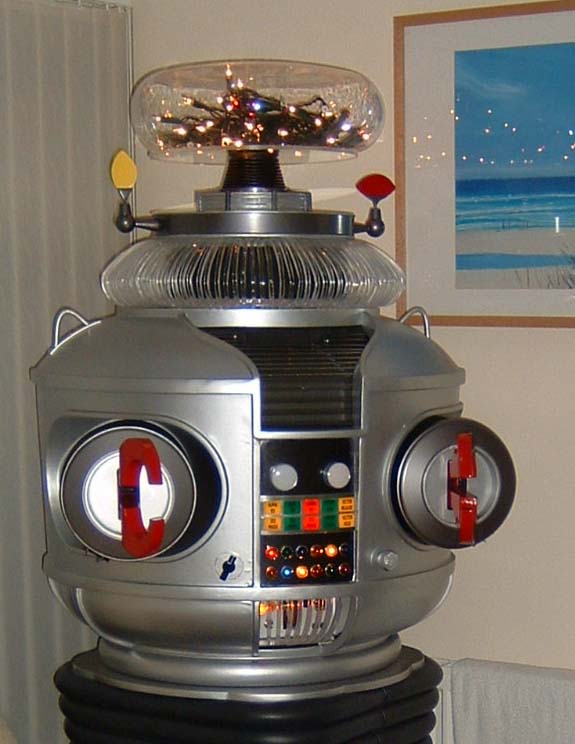

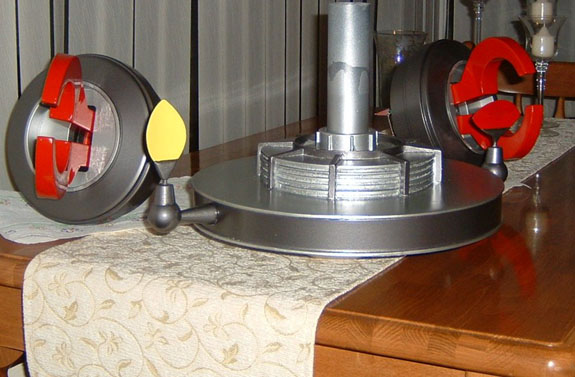

Ears were bought from Craig R. He had a spare set in CNC machined aluminium .

I also bought the small motors that we all use now & used brass bar(7mm OD x 6mm ID) to house them in the Ears.

I also used 3mm OD x 2mm ID Brass bar to attach to the motors for my Radar Ear spinners.

A grub screw was added to the spinners after cutting a small thread in them.

I also rewired the Brain but did not photograph any of the work unfortunately.

I also added a mono amp, jukebox SD memory card music board & small speaker. This is for the Robot noise only.

the volume is controlled on the front programming bay panel.

I upgraded the main robot sound system with a high powered Stereo Bluetooth amp & 60watt Speakers.

Here are some pictures:

I made another tread section (3rd one).

This one is plywood with plastic & aluminium skins.

Not much to say on this but I put new oil light bushes in the wheel centres, bought new wheels & tires for the drive motors.

My treads are slightly raised on the front to enable the drive wheel to run freely.

The treads rest on the rears for stability & to make the rubber treads move.

I have had this setup working since 2006.

Here are some pictures:

2008

12/20/2008

I have fitted the bezel all is working fine with my B9 here are

the updated pictures.

12/13/2008

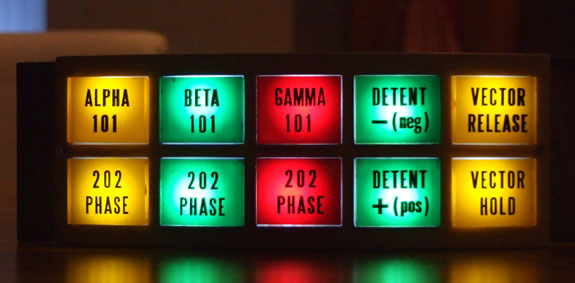

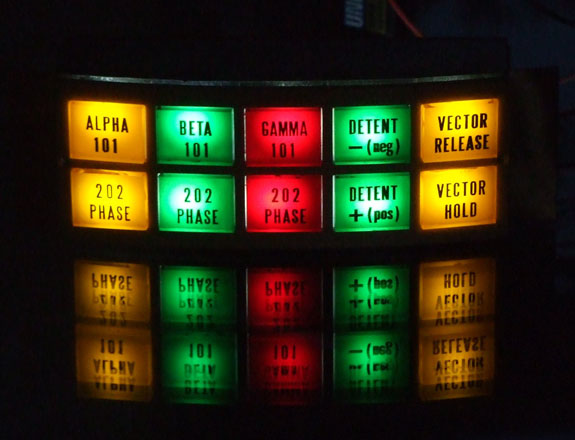

I have at long last completed my bezel button box

I have divided

it into 10 sections and each one has a 5mm ultra bright led in

it I chose the narrow beam to attempt to recreate the effect of

the replica

To my great

amazement I have managed to get the desired effect

Here are some

pictures of the bezel and box – I will be fitting it this

weekend

2007

11/26/2007

I hope you all had a good thanksgiving Holiday.

Well here

we go I hope I explain this ok as the video shows everything but

I am sure you will have questions.

Here is the

Youtube video

Right – I’ll

start with the list of components I used for this:

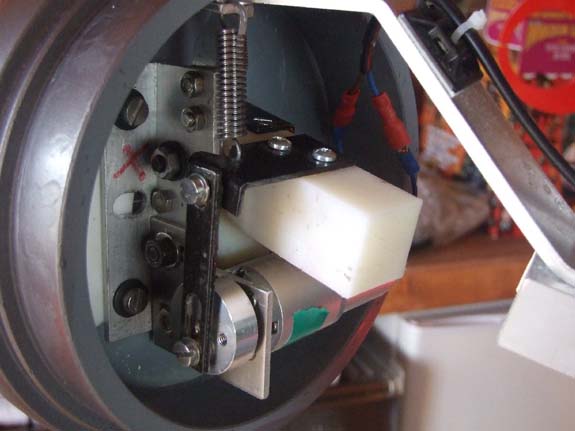

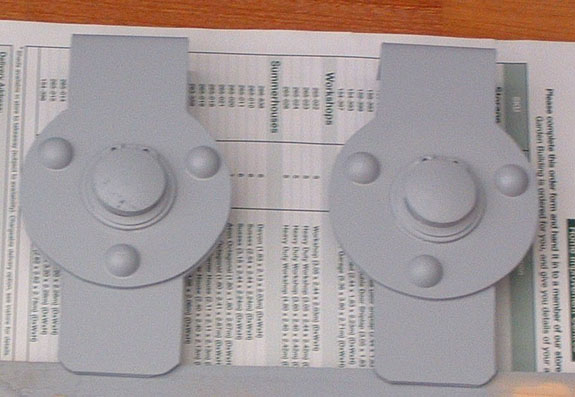

1 pair of nylon Wrists

(CNC machined)

2 pair of nylon claws

(CNC machined)

2 Maplin motors 12

volts ratio516:1 (as seen on the b9builders website under off

the shelf)

2 pulleys 2 springs

and some steel plate and 90degree steel section for the brackets.

I initially started

with the new nylon claws; the 4 were made as per the Dave Painter

drawings:

Then I had

to modify them to suit the mechanism – sorry you will need

to see the video attached but the only thing is that

the lower claw has been cut off a lot shorter than the top one

and the end of the lower claw has been rounded in a very similar

way to Mike’s Replica claws but without the teeth.

Next was to make the

mechanism which is again shown on the video

The Pulley is attached

to the top of the motor then a hole is drilled on the edge and

a bolt is inserted with a very small sleeve and bearing then a

piece of steel was added which was then attached to the top claw

via the bracket (seen in the video) a bit like a big end in a

vehicle engine. The top bracket is then attached to the wrist

with the spring to allow the claw to move all of the work is done

through to top claw.

On the far side of

the claws are 2 more pieces of steel which are joined between

the claws and have a pivot point to allow the bottom and top claw

to move at the same time the rounded of part of the bottom claw

is also moved when the rear of the top claw is in the downward

movement.

Again apologies to

anyone if this was a bit confusing, I must say it seems a lot

easier to put the pieces together than explain how it all works.

I have one note on

the springs I used I decided that all I would need would be for

my B9 to handle pretty light objects so I used quite a weak spring

This however can be

replaced with a stronger one if needed; i have kept with the ones

I used because if you put your hand, or more importantly a child

was to put their hand in the way of the claws they won’t

get hurt as the claws will still run but not try to crush.

I was still able to

get my B9 to hold a can or bottle or letters etc.

He was able to hand

the envelope over with no problems at the award ceremony I attended

the other week and from my point of view that is fine

When I was at the space

centre he did take a soft toy from a little girl (who was being

held up by her father) passed it to me then I gave it back to

him and he then gave it back to her. That was a good test too.

Well I hope this covers

everything and please let me know if you need any additional info

or help on this.

I have one

final thing to say and that is if any of you have information

and diagrams of making the B9 slump forwards when the power pack

is removed and stand up again when it is re-inserted please let

me know as I am currently looking for a set of second hand Dewey

style rubber legs and will do this as my final upgrade (for now).

11/08/2007

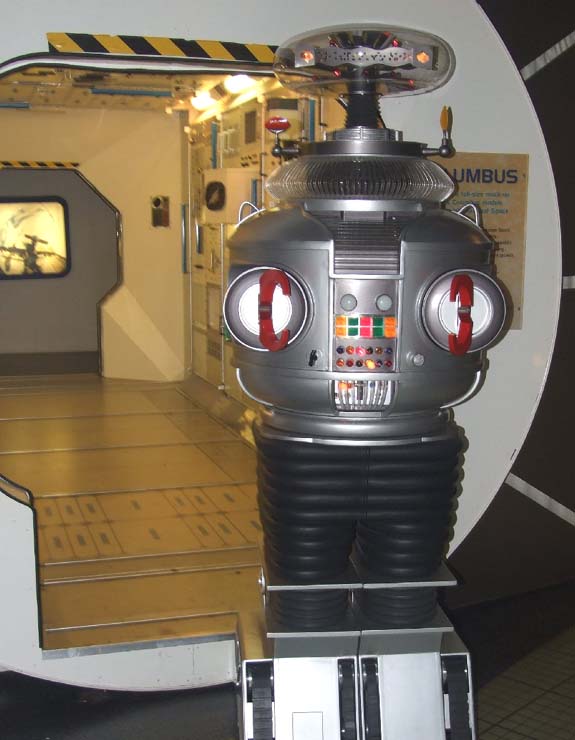

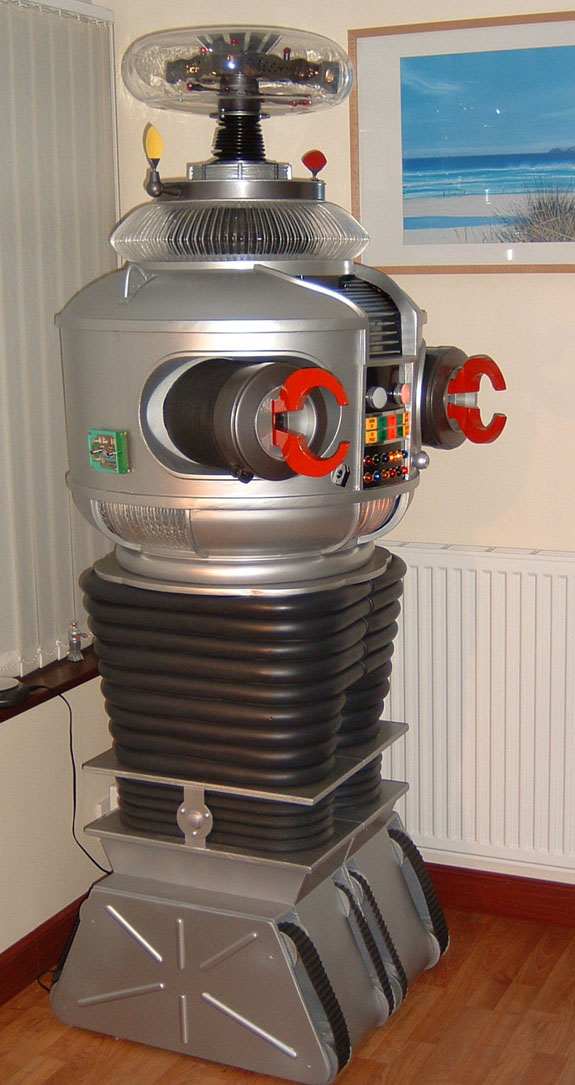

Here are some Photos of my B9 while attending the Sci-Fi Weekend

at the UK National Space Centre.

07/04/2007

Here are a couple of pictures from the UK robot builders meeting

I attended Saturday. There was a lot of interest in

my B9 by the way.

I have at

last installed my dataplate, Here

are a couple of pictures:

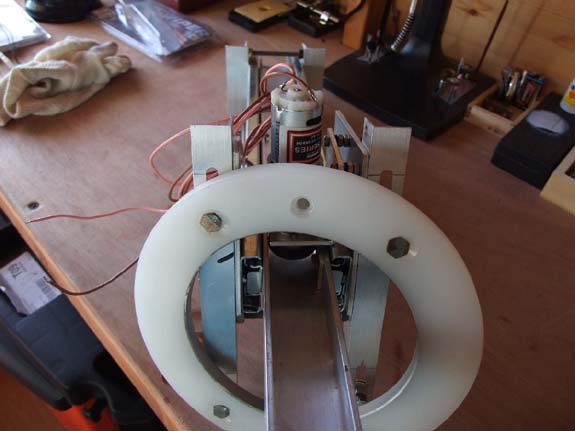

05/22/2007

Hello everyone

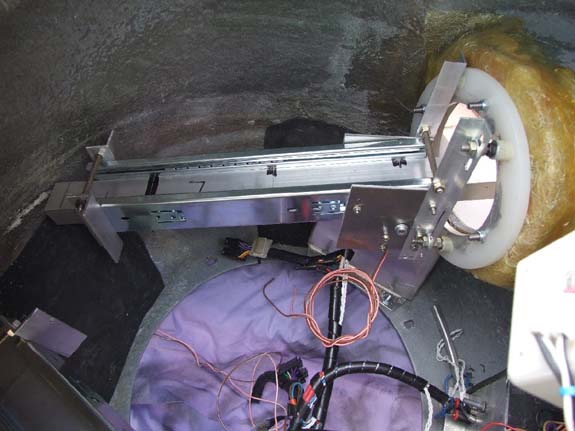

Here are my pictures of the arms mechanism it looks complicated

but it is only 2 14” drawer runners with some aluminium

plates and another of my 516:1 motors as I used on the brain torso

& ears they are very good motors so it should last for a while. The

2 motors are attached to a speed controller as seen I one of my

pictures enclosed.

Please let me know if can provide any additional info on this.

Paul

Hi-Res

Photos Zipped

05/18/2007

Hello everyone,

Please find attached 2 small videos of my completely motorised

B9. I have spent quite a few weeks now getting the arms

motorised and today they were fitted. I have many pictures

of the process piece by piece. I can only say that my B9

is really alive now – It was very satisfying to see the

arms move on their own. I

hope you all enjoy the videos.

Paul

Video

# 1

Video

# 2

03/28/2007 Hello

All

Just

a final picture of my B9 with his new bubble in place. Becky

(my daughter) took this picture, tomorrow we start fitting my

new arms from Vince with the mechanised components. I’ll

keep you posted on the progress, hopefully I’ll have some

DVD footage to bring to Denver as I am going to do some filming

of the B9 in action in the garden.

Paul

Here

are some pictures of my B9 wearing his new bubble.

03/09/2007 Hello

All

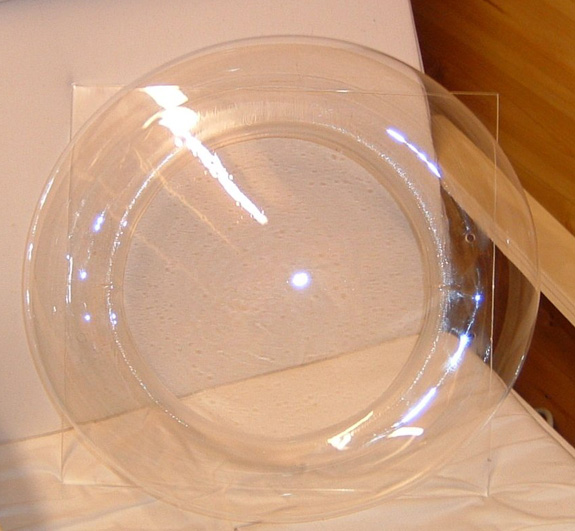

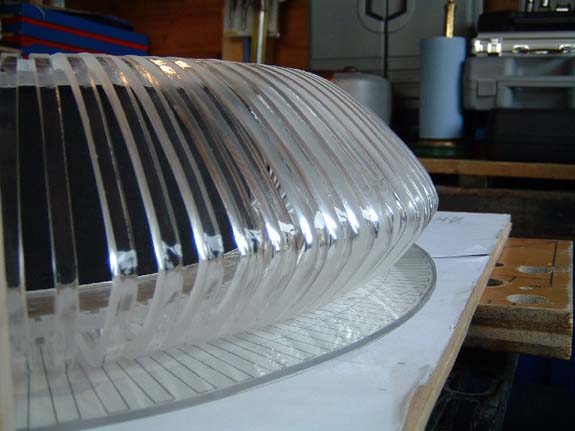

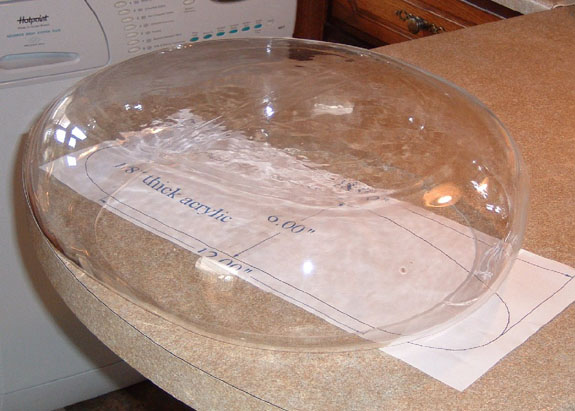

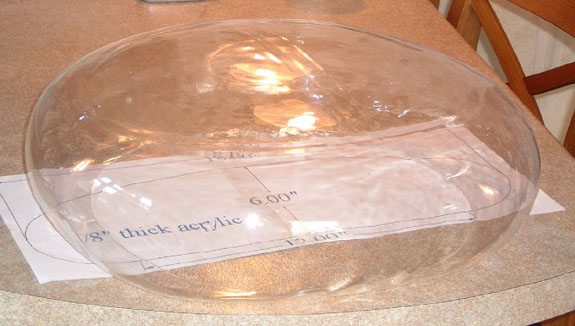

As you

all know I have been trying for quite a while to create an 18inch

Bubble for my B9, well tonight I have had 100% success.

I blew

2 bubbles and they both came out great.

Here

are some pictures – my B9 will be wearing one of them very

soon, but I will have some spares, as next Thursday I will make

some more 2 maybe 3.

I must

say this has been a great sub project for me and I have enjoyed

every moment of it

Paul

(B9-0203)

2006

12/19/2006

Hello Everyone,

I would just like to wish you all a very happy Christmas and prosperous

2007!

Thanks again for all the continued help and support.

Paul

(B9-0203)

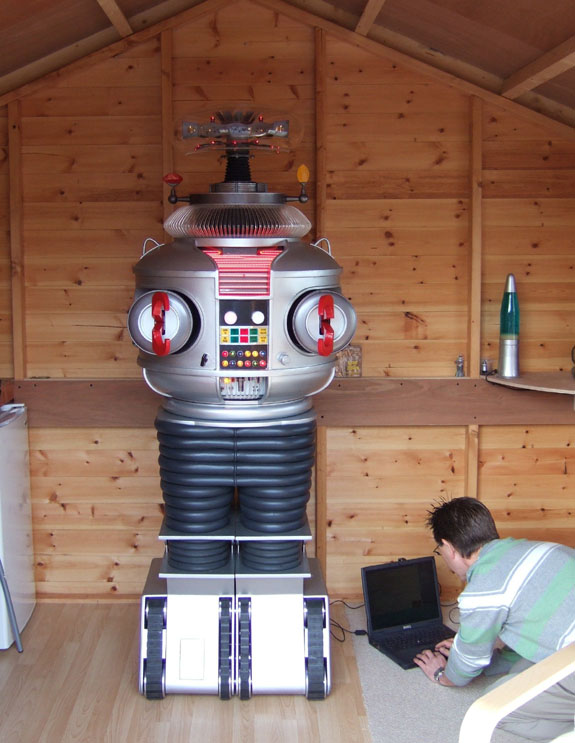

My B9 has a new home – a 16x12foot workshop in my garden

08/20/2006

Here are some pictures taken of my B9 a couple of days ago.

I have

upgraded him with new nylon wrists and claws; the new bubble is

in place with its new bottom plate.

The

motorised ears and new sensors are fitted.

I am

still working on getting the bubble sorted but the only problem

I have is with the acrylic at the moment.

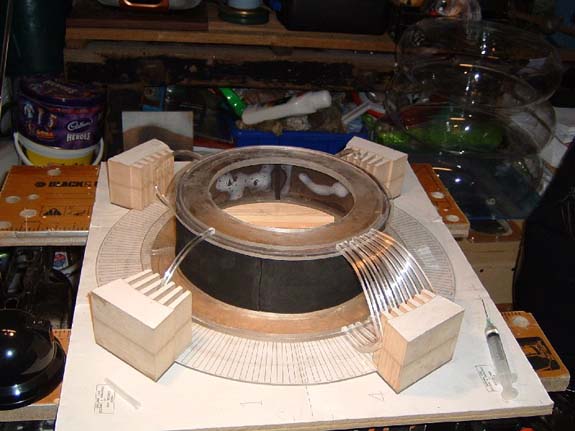

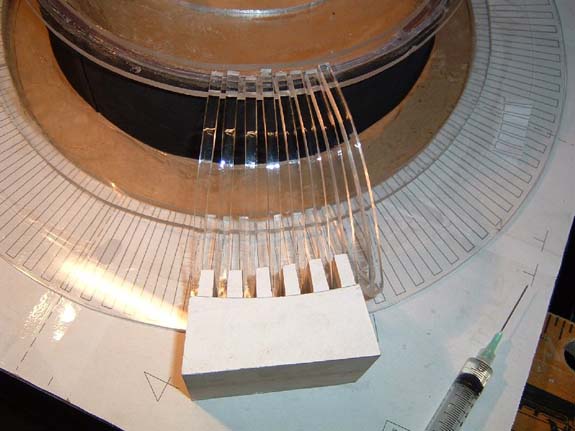

06/17/2006

Bubbles

Hello everyone,

As you all remember I was looking at blowing a bubble for my B9,

well tonight I have had some success.

I have

blown 2, 1 at 18inch diameter & 1 at 17inch diameter, and

yes they are circular too!!.

Here

are the pictures plus my thanks have to go to my neighbour Craig

who supplied his large oven again.

Plus

my other neighbour Alan (Cole) who made the compressed air box

and the input regulator valve from an old bicycle inner tube.

He also supplied the air compressor.

I will

be blowing some more next week which should complete this part

of the project I have learned a lot from this experience and have

really enjoyed it.

Hope

you like the pictures - Paul

05/30/2006

Motorized Ears & Additional Info

Firstly Thanks

again Scott for these great ears I have at long last installed

them and motorised them.

Here

are some pictures of my drive assembly; it consists of O rings

and nylon pulleys made on my neighbour’s small table top

lathe.

I did

start out with elastic bands but the O rings worked much better.

I have

1 final update in progress – a new Bubble created with compressed

air with a whole new system I have created

Hopefully

I can make it this time – I have had some good advice from

some people from a helicopter manufacturing company (Westland

Helicopters they make the Apache)

Some

Info on my B9 Setup

The 12 teeth/belly

lights are the ones from Allied Electronics from the club site

under parts then under off the shelf and my bulbs are 12volt,

my Torso motor is in here too , I infact have 3 of these in my

B9 , 1 for the Brain 1 for the Ears and the 1 for the Torso. To

get the 2 patters was a complete fluke;

The light controllers I have in my B9 are from a company here

called Maplins (www.maplins.co.uk)

The light controllers have 10 channels and have 2 buttons, 1 for

the light pattern and 1 to switch the lights on & off

There is also a rotary switch to change the speed. I have 2 bulbs

in parallel on each channel I used 8 channels 6 for the teeth

and 2 for the big chest lights all my lights in the torso are

12volts.

I have now updated the bottom row and they run in the opposite

direction to the top row so it’s a bit like the car KITT

from Night Rider.

The treadsection motors – I managed to find a local wheelchair

repair centre and just by chance the chap there was getting rid

of an old obsolete electric wheelchair it had 24volt motors with

the shaft set at 90degress offset to the motor body.

I tried and tried to use my rubber treads to drive my B9 but I

couldn’t get it to work as I would like so I copied the

layout of a small radio controlled Dalek.

I used the front 7 ½ inch diameter wheels from the wheelchair

and attached them to the motor shafts then I mounted the motors

as seen in my scrapbook. I decided to set it up so the wheel is

¼ inch lower than the treads to the ground to reduce the

drag then the rear of the tread section rests on the ground and

the belts rotate as if they are driving. The raised ¼ inch

does not show especially when my B9 is on carpet.

The batteries inside my B9 are 12volts and the motors (24volts)

are only running 50% when I have him moving flat out which is

about the same speed as he moves on the TV. Plus the motors are

never under any real load

With

the radio control I used a 4 channel system with 3 speed controllers

1 for the motor that drives the torso via the lazy susan. And

the other 2 drive the tread motors. When I asked for help from

my local radio control shop I realized the B9 is setup like an

R/C Tank. Left and right motors forwards and reverse for mobility

then the torso rotates like a tank gun turret.

04/04/2006

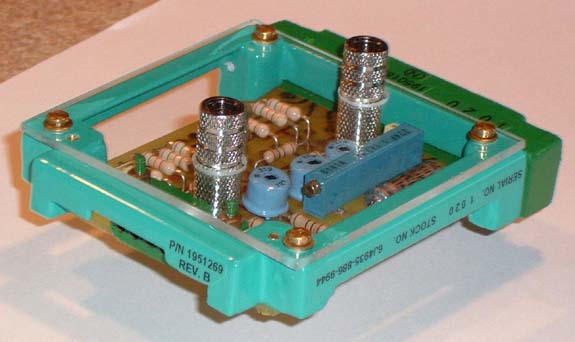

I would like

to say Thankyou to Craig for his sensor instructions – I

used them again.

And

I have a new set nearly ready for fitting, picture below.

Plus

here’s a picture of my new neck from Vince in place also

nearly forgot I just made the new light box for my.

Chest

bezel here’s a picture of that too.

03/27/2006

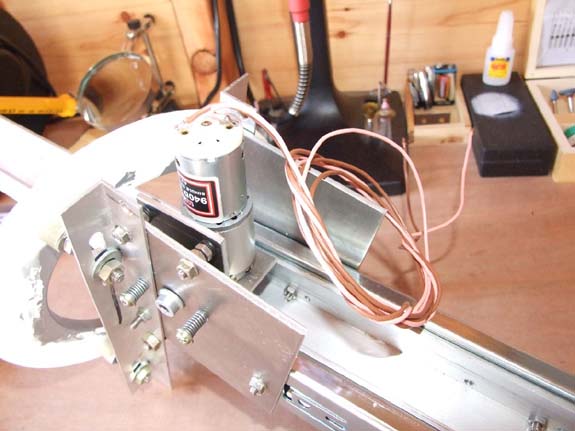

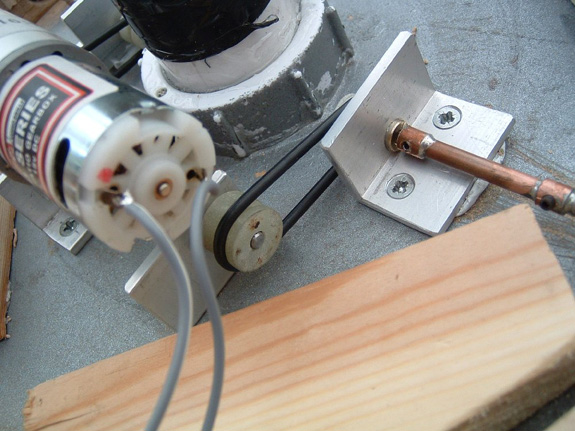

To motorise

the treads I had to rethink my method here are some pictures.

I used 2 wheelchair motors 24volt 6amp but by using 12volt input

the B9 runs slower and is easier to control.

I also

enclose a couple of pictures of my torso motor – the same

as I used in the brain but with a spring loaded bracket to alter

tension etc.

With

regard to the radio control the torso motor is just the servo

pushing and pulling a switch to switch the motor on and of in

forwards and reverse, plus my two tread motors are controlled

by speed controllers.

Here are a

couple of movies:

B9001.WMV

B9002a.WMV

01/13/2006

Motorized

Tread Section Upgrade.

I have

the motors ready to install in the new treadsections and I now

have a new waistplate too. I

will fit the waistplate when I install the lazy susan cover.

Here

are a couple of pictures of my new parts.

2005

10/11/2005

I have some

picture updates of my B9 taken today, it’s the last ones

before the radio control upgrade.

I have

had one of the pictures made into icing and it has been put onto

a birthday cake for me this Thursday, I will be 44 (oh the pain!)

Hopefully by

Halloween my B9 will walk rotate (left and right) and talk!

09/09/2005

Hello All

I have

been very busy lately and apologise for being out of touch.

However

I have made a new MDF donut and I have a set of rubber treads

and aluminium wheels nearly finished including full remote control

of my treads and full automation of my torso for rotation.

The

torso will rotate 90degrees left and 90 degrees right.

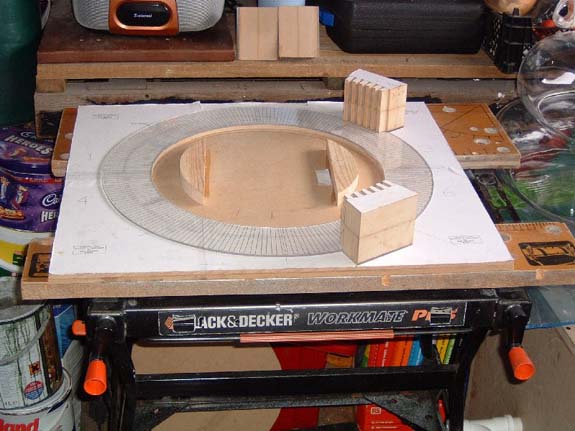

The Donut

work was extensive initially I asked Mike J for dimensions which

worked out great thanks Mike!

My friend

Alan told me to get 4 pieces of 12mm MDF which I purchased, then

he stuck the four together and cut out the circles for me, and

then he used his router to cut the .88 radius for the donut

Then

I had the job of priming filling and painting etc.

Enclosed

are my progress pictures the priming wet and dry and filling was

a case of doing this 4 or 5 times but I am happy with my new donut

and will be fitting next week the priming etc took 1 week.

In 2 weeks

time I’ll be upgrading the tread section so I’ll be

sending some pictures etc then.

Paul

06/15/2005

Hello All,

Here are the pics of the completed B9 with his powerpack in place. Hope

you like the pictures.

Paul

06/14/2005

Here are 5 pictures of my powerpack complete with the decals I

am really pleased with it and now I have to drill the 3 holes

in the Torso.

I’ll

let you know how it works when I have it installed.

Thanks

again Mark for all your help it really is appreciated!

Paul

06/02/2005

Hello Everyone

I have fitted

the new collar to my B9 and at the same time raised the Bubble

to give the same look as in the TV series.

(or as close as I can get).

Plus here are some sneak preview pictures of my Powerpack courtesy

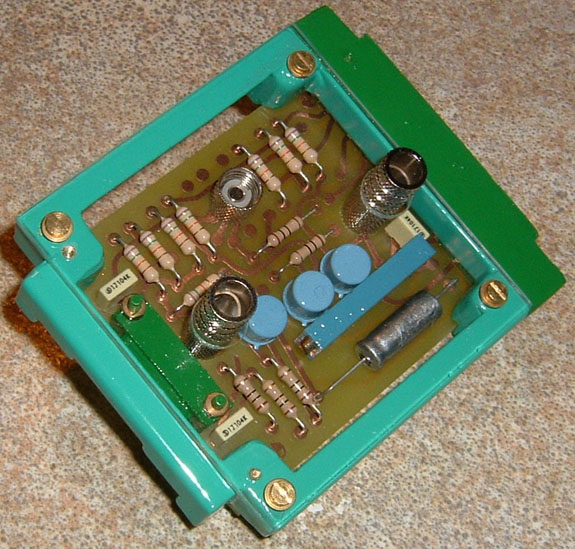

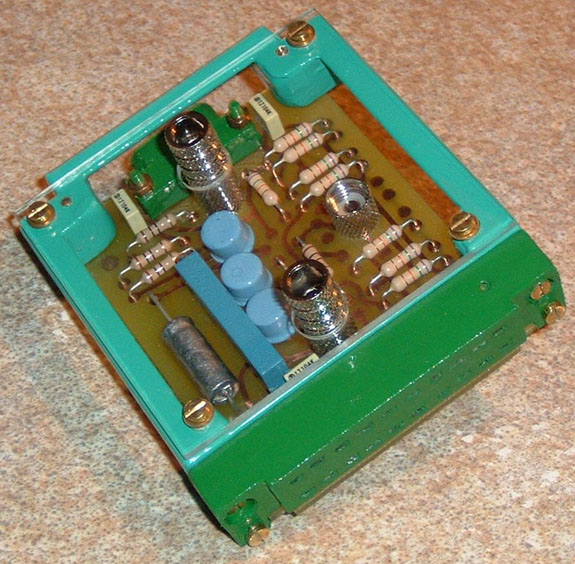

of Mark Wees instructions and the Ppack board he gave me.

I couldn’t get all the original components but I am pleased

with the pack.

All I have left to do is to install the decals which are being

printed at the moment plus I have to install the copper/brass

Pins

into the 20pin connector which I made from one piece of nylon

and I used a hot screwdriver to make the 20 indents.

When

I have the powerpack fitted I will send an updated set of pictures

of my B9 complete (with his Powerpack!!)

Paul

05/20/2005

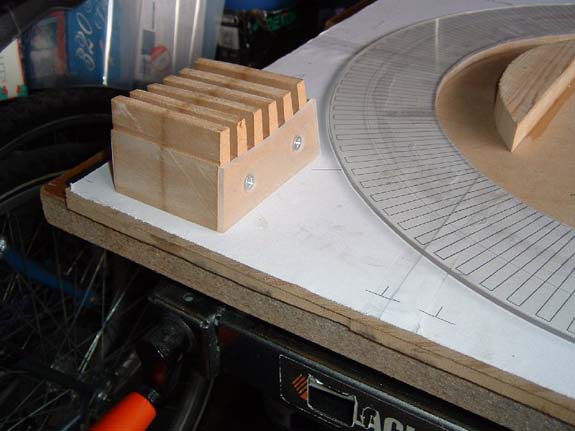

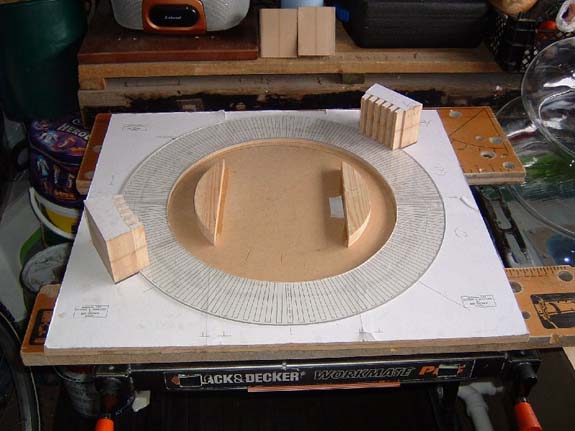

Hello All,

Here are the pictures of my collar setup I used Bob G’s

6 page layout for this. I put a 3mm piece of acrylic

on top of the layout to give the ribs a good flat surface. As

I made a cylinder in the centre of the collar this time I put

2 locating pieces of wood to centralise the cylinder. The

jigs my friend Alan made included a piece of the 3mm to enable

to jig to locate up to the edge. To make to jigs Alan

took a piece of the layout glued it to a piece of MDF and cut

out for 5 ribs on the bandsaw. We discovered

the jigs with the short rib holders worked as the longer ones

would not slide back away once. The ribs were in place.

Alan has to take most of the credit here as he provided all the

wood cut out and made all my jigs including the rib one. Alan

has been a great help to me on my B9 Project. As you

can now see my finished collar looks much more like the real thing. My

2 local helpers have been great and have also taught me some new

skills they are:

Alan Cole from above in this email.

Pete Davidge, my neighbour, he made many bits for my B9 plus he

soldered my 2 light control boards from the kits I bought. Pete

also made the frame on my power pack which is in progress right

now he said he wanted to take a look at my instructions from Mark

(Wees) and came back over to me later in the day with the frame(brass)

soldered together.

I owe

both these guys a lot!!

Paul

05/18/2005

Hello

Everyone,

Here

is a small movie of my B9, my daughter Lucy enabled him to move!!

Paul

Click here to download or play

Windows Media Clip -B9.wmv

05/15/2005

Hello All

Here

are some pictures of my new Collar.

I used Bob’s Layout again and have glued it to a piece of

MDF then glued an acrylic disk over the top.

I have

dry installed all the ribs so they are not evenly spaced.

However

my friend Alan is making a jig to hold 5-10 ribs so I can glue

them and ensure they are all parallel.

I will

send pictures when I have the jig so you can all see as it may

help others.

The

pictures enclosed today are the collar with the 108 ribs dry fitted

plus some of the collar chassis with its shroud in place.

I decided

to have an acrylic cylinder inside the collar to strengthen it.

The shroud is glued to the cylinder.

I put

my recent bubble with it just to check it with the collar size.

I’ll

keep you all up to date with the powerpack too.

Paul

05/13/2005

Hello Everyone

I have been upgrading my collar on my B9 as my first upgrade.

I was never happy with the way I built it so I have rebuilt the

jig and have remade the 108 ribs

I put a piece of clear acrylic on top of the jig and all the ribs

are flat and straight.

The failings of my first collar were down to me not being patient

enough – Bob’s plans however were super as I reused

them again I have enclosed 2 pictures of the formed ribs as you

can see they look correct this time. I’ll

send a picture of the completed collar.

Bubbles

I have been able to make 2 new Bubbles one was 16½ the

other however is 18”!

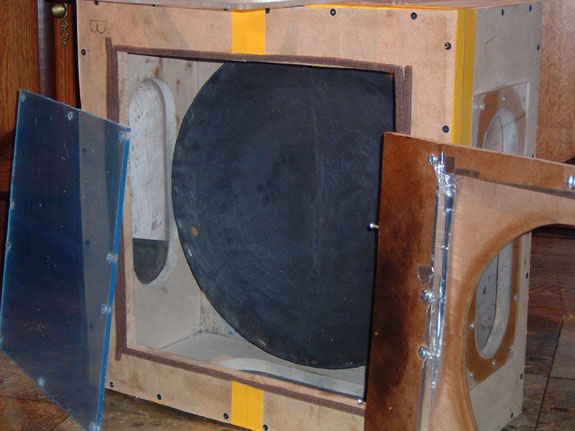

I have also enclosed my bubble box and some assorted pictures

of all the bubbles etc.

I still cannot get it 100% round but it is nearly there and I

cannot notice the slight off round when the bubbles are installed.

In the picture of the 3 stacked bubbles the top is 16½

the middle one is 18 and the bottom one is 19½.

I am

also working on a powerpack too – Mark Wees very kindly

sent me a circuit board and a set of detailed instructions.

Which

I am very grateful for. I’ll let you know how the

Ppack comes out.

Paul

04/22/2005

Hello Everyone

Now

I have completed the build of my B9 I would like to thank you

all for making this possible for me:

Mike

Joyce – for making the B9 builders club available and for

the superb Torso, Torso Switch, the

personal Dick Tufeld CD and many hours of helpful tips and guidance.

Mark Thompson

– Mark got me started with the whole bottom half of my B9

from the Treads to the donut. Plus Mark gave me a set

of eye lenses for the brain.

Bob Greiner

– With Bob’s help and guidance plus his excellent

website I was able to make the Radar, Collar, Torso Vents and

Knee hinges.

Craig Reinbrecht

– Craig has helped me with the chest bezel the programming

bay Neon Wiring and the sensors plus the ear posts plus many drawings

of the braincup with the cam etc Craig sent me a diagram of the

wrists from which my friend was able to make a set of Aluminium

ones! Plus many hours of help and guidance with building

my B9.

Dave Painter

– Dave sent me a diagram for the Brain, braincup, crown,

and brain rods. From this I was able to make the components

plus a claw diagram which enabled me to make a set.

Dennis Wilbur

– Dennis sent me my Neon and Torso hooks – plus a

diagram from the B9 helpers of the dialights from which I was

able to make a set! Plus

again many hours of advice and guidance.

Between you

all I was sent many additional diagrams and information that has

become invaluable for me in the build process. Thank

you All again I really have appreciated everything.

Thank you

ALL for all your help and support and I will be asking more questions

when I start Phase Two...

I will

take a break before I get into the real robotics!!

I've

also enclosed a shot of him just before I started to re-assemble

him. From an extremely happy B9 Builder, I hope you have

a good weekend.

Paul

04/21/2005

Hello Everyone

I have made the knee hinges for my B9 (Thanks again Bob (G) your

website gave me all the info to build these!!)

Here are the pictures.(I only photographed one set as the others

are being made right now.)

Assembled, primed & finally painted ready to fit – I

will be fitting them Friday Night.

As soon as they are fitted I will take some full size photos of

my B9 and send them over, this will be phase one of my B9 completed.

Thanks

again to ALL of you for all your help over the last year without

all your help I wouldn’t be anywhere near where I am with

my B9.

Paul

04/06/2005

Hello Everyone

Here

are my most recent pictures of my B9 I just have the knee hinges

and a slight mod to the neon Backplate to do.

Hope

you are all well.

Paul

04/03/2005

Hello Everyone

I feel

as if I am on the home stretch with phase one of my B9 –

just the knee hinges to make & fit now.

I have

however just started on my replacement collar as I wasn’t

completely happy with my first attempt.

This

will be the first part of phase two.

Just

like to you all to see these updated pictures, I have completed

the brain, braincup & crown plus I have installed the motor

for the crown and the brain rods. My Torso knob controls

the speed of the lights plus my programming bay has four switches,

2 to switch the lights on and off & 2 to change the sequence.

I have four as I have two light control boards installed,

one for the brain and one for the lights in the main body (Dialights

and the 12 belly lights).

Have

a good weekend all of you.

Paul

03/17/2005

Hello Everyone

Just

a quick note to say I have completed my B9 Brain, However this

was only possible by Mark (Thompson) as he sent me a set of Lenses

which fit great.

I would

also like to thank Dave (Painter) for the original brain drawing

as without this I would have no brain; (this sounds a bit like

a quote from the Wizard of Oz!!)

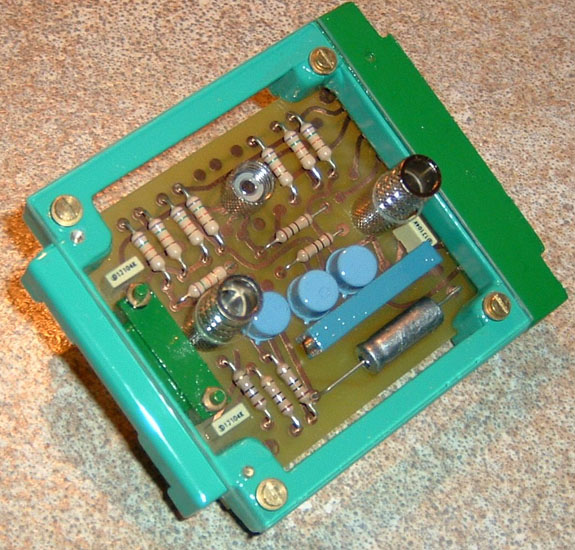

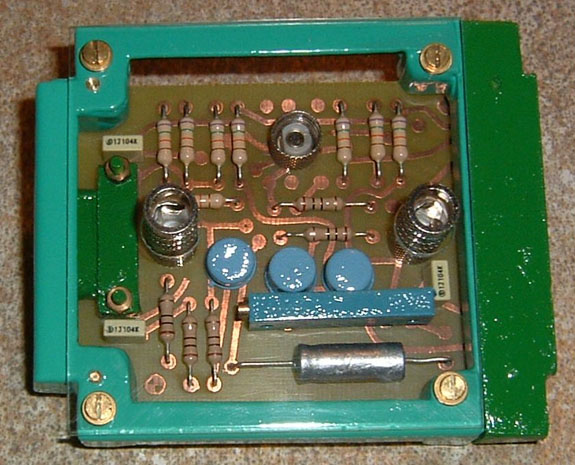

In the

5th picture the circuit board is a light control board I already

have one of these controlling the torso lights , in my programming

panel you can see 2 black buttons on the right hand side one of

these control the light sequence and the other toggles the lights

on and off.

I hope

you all have a great weekend

Paul

02/28/2005

Just an update

really as I am building the brain at the moment I am using Mike

Lowen’s instructions from his website but I made the brain

from 3mm acrylic and the surrounds are made of Foamex which is

the same as sheet styrene. As

you can see I have some cutting out to do!!

I have included

some pictures of my B9 as I have already made the brain cup and

light rods plus the crown. When this is complete I will

have another go at a perfect bubble. My box has been upgraded

so I can test again next week. I also have the knee hinges

to make and I am using Bob G’s for this as his instructions

are great.

Paul

02/15/2005

Hello Everyone

I have been

seriously researching how to make the bubble for my B9.

I was able initially to make a 16inch one but have been able to

make two further ones.

One

is 17 ¾ and the other is 18 ¼.

Unfortunately

I couldn’t get the bubble completely round it did go slightly

oval on one side which I have put at the back.

The

other small problem is the fact I used wood for my dish inside

the vacuforming box and when the wood heats up the grain starts

to raise and imprints into the top of the bubble, it is very slight

but I can see it if I look closely.

However

if I look at the bubble straight on it looks fine.

Here

are a couple of pictures.

The

bigger bubble is the one without the lights in(bubble…)

as I am building the brain at the moment.

Paul

02/04/2005

I am currently

researching how to make a bubble for my B9 and have read the article

from TerryM on the B9helpers. I spoke to my father in law

who is a carpenter and he made the box – I was able to get

an 18inch dish made from wood as per the instructions. I

have however used a few pieces of ¼ inch acrylic but have

made some good progress. I had the bubble forming very

well the other night until my vacuforming box lid broke. I

have enclosed some pictures of my 16-17inch bubble, just for effect

I put Xmas lights into it jut to see how it looks. I

will be trying to make the bubble properly over the next week. I

will at some stage buy the Fred Bubble but it would be good for

to have a backup bubble just in case!!

Here

are my Pictures I will let you know how I progress with this.

2004

10/26/2004

Hello everyone

Just a note with some

pictures of my up to date progress.

I have completed

my collar - thanks again to Bob(G) for the info on his

website.

As you can see I have at last started on the B9Creations

Torso (no longer available). All the holes are cut and I have primed it so

I can see where I need to fill, sand etc.

Fortunately, I don't have much work to do as the Torso is excellent.

I would like to thank you ALL as without your help I would have

NO B9.

I am working on the prgramming bay & Torso vents now.

I have a weeks vacation so I am hoping to get as much completed

as possible.

Thanks

again guys I hope you enjoy the pics.

Paul

10/13/2004

Hello

Everyone,

Here

are some pictures of my completed wrists,claws & radar.

I saw Mark's Picture of the 2 colour Radar & have painted

mine the same. You are right Mark, it looks much better.

I have now started the process of the collar.

Paul

10/07/2004

Hello

Everyone

Here

are a couple of Pics of my B9. I have not put the donut

in place as it is ready to go on the finished robot so it is stored

at the moment. I made the side panels from MDF & half

round dowels. I studied my 2nd season DVD to get the angles etc

as close as I could. I have however today painted the Radar

in the two colors, I will send a photo later. So here is

the current progress, next job building the collar, then to the

torso!!

Paul

09/27/2004

Hello

Everyone

Please

find below my finished Radar.

I decided to take BobG's advice and improve the 1 3/4 band around

the radar.

I was able to obtain an aluminium strip which i attached.

I have a photo of the Radar re primed and one of the completed

I also made the sensors using Craig's info from the club (Thanks

Craig)

I couldn't follow all the instructions but was a ble to make the

sensors

and mount them on the epoxy putty that goes as hard as stone after

a couple of hours

I sanded this and painted.

Next time i will try and make the complete ones!!

I have

my MikeJ Torso (thanks Mike)

That is my next big task !!

Paul

09/20/2004

Hello

Everyone

Below

are photos of my Radar, it just needs its final coat of paint

when I assemble my B9.

I must take this opportunity the thank Bob

G. for the instructions as without these I would have no Radar!!!

As

you can all see the ears are slightly narrow at the sensor end

but as i have no lathe and had to use my drill as a turning device,

it was the best I could do as an initial go. The rest of

the ears are a wooden ball from a craft shop and a wooden flowerpot

from the same shop with the top lip cut off (the ball is 1.25

inch diam) and the flowerpot is .75 of an inch. I used

the diagram so kindly sent from Craig R. the drawing was from

Dave(P) so thanks again to Craig & Dave.

Thanks

again to all of you for your help, guidance & advice etc.

I will keep you all up to date with the project as it develops.

Paul