Previous

Entry Top Next

Entry

10/05/2004 - Homemade Motor Shaft Encoders

WARNING!

This topic is not for the technically faint of heart! It

really only applies to folks that plan to use some kind of computer

control of motor functions. With that said, I will

describe what I'm doing as best I can but some knowledge of

micro-controllers, quadrant encoders, etc. is assumed. Tons

of info on these topics can be found by searching the internet,

your library, etc.

The

Problem

It's all fine and dandy to talk about a computer controlling

a motor but in reality several things have to happen to do it

correctly. To start with, you have to have some way to

control the motor's speed and direction. Since I'm

using the OOPicII as my

micro-controller Magnevation's

Motor-Controller seemed like an easy solution. OK,

that solves the control problem. Now for the hard

part. How does the OOPic keep track of the position of

the moving part? I'll illustrate this problem with

an example.

Torso

Rotation

Mechanically I have a motor with a wheel on the shaft. As

the wheel turns it contacts the CSS plate causing the entire

CSS and torso to rotate. With my Magenvation Motor-Controller

the OOPic can be programmed to rotate the torso left or right

at different speeds. BUT, it has no idea which direction

the torso is facing at any given moment. I have decided

to solve this problem using two sensors. First, a

simple "on/off" sensor will detect if the torso is

turned toward the left or right hemisphere (more on that in

a later update). Second, I will use a homemade quadrant

shaft encoder for the motor. In simple terms, the

shaft encoder will allow the OOPic to keep track of the rotation

of the motor shaft by counting (either up or down depending

upon the direction of the motor) every time the shaft turns

5 degrees. The OOPic will use these two sensors to keep

track of the torso position. (The OOPic will reset an internal

counter to zero when it detects the straight ahead position

which is defined as the transition of the left/right sensor

from one hemisphere to the other.)

The

Shaft Encoder

Well, I could buy a nice motor with a built in shaft

encoder, but they can cost hundreds of dollars each

and I need five of them (Hip, Torso, Left Arm, Right Arm &

Bubble lifter). So, it's time to get inventive. The

Dewert motors I used last time worked great and only cost about

$30 each. Also, they have a nice gear box cover that

can be modified to work with my encoder mounting idea. Now

I just need some cheap encoders, so off to Wal*Mart I go. For

less than $10 I found a cheap two button mouse. Now

a mouse just happens to have TWO encoders (x&y axis) built

in, so each mouse yields two encoders for less than $5 each. Here's

a photo of the Mouse I decided to use. It's a Micro Innovations,

Two Button, PS/2 Mouse, Model PD39P.

A

Rough Guide

What follows next is a rough guide showing how

I extracted the encoders from the mouse and mated them to the

Dewert motors. It should be noted that the mounting

is critical! Failure to position the encoder sensor

correctly relative to the encoder disk will result in junk. I

designed special mounting plates based on this specific model

of mouse using CAD software. I had those plates laser

cut from hard ABS plastic. You could try to make

these plates by hand but it would be tough to get them accurate

enough, IMO. The other tricky part of this operation

is drilling and tapping the main motor output shaft. I

used my lathe, drilling it in the exact center without a lathe

is not impossible, but it would be very difficult.

How

To Destroy a Mouse

I began by taking the mouse apart. Take out the ball

and remove the single screw.

Here's

a shot with the cover off. Note the two encoder disks

and the two encoder sensors. Each encoder sensor consists

of an IR LED and a pair of IR sensors in a tiny black package.

The pair of sensors are slightly offset such that, as the encoder

disk rotates, each one turns on/off out of phase with the other. This

allows one to be used as a counter and the other to be used

as a direction indicator, in other words, a quadrant encoder. (The

OOPicII has code that handles Quadrant

encoders.)

Here's

a shot of the mouse components with the circuit board removed

as well as one of the encoder disks removed.

Here's

a "before/after" shot of the complete circuit board

which also shows two encoder sensors that I cut off another

circuit board. Also shown is an encoder disk I just

removed and another that I have modified by cutting off a portion

of the shaft and then cutting 8-32 threads.

Here

are the two laser cut encoder mounting plates along with the

sensor and disk. The plates are specific to the sensors

and won't work with other mice, but here are the blueprints

(dxf format) in case they help you. ( Top

Base

)

Close-up

of the top cover with the sensor and the disk.

Close-up

of the top cover with the disk and sensor in place.

Close-up

with the bottom plate in place. These photos are just

to illustrate how the cover holds the encoder in the correct

position.

A

shot of the five Dewert motors prior to modification.

How

to order Dewert Motors:

General

sales number: 301-228-3315 Steve W. Rose (Sales Department

Director)

Very Important

- Start out the conversation telling them that you are with

the the B9 Robot Builder's club and you want to order gear

motors - Part Number 000.002.016

You have

to order them by calling during normal business hours (EST):

(you can not order from their web site)

They are $29.50 each as of Nov. 3rd, 2004 They accept Visa

& MasterCard

Tell them how you want it shipped, UPS Ground, Blue, Red.

Cost of shipping is added to your card depending on quantity/weight

and where/how they're shipped.

Using

a band saw to cut off the four rivet heads to allow removal

of the gearbox cover. Be Careful!

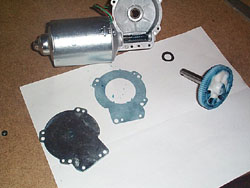

A

shot of the motor after removing the cover. Note the motor,

cover plate, gasket, shaft with gear and washer. Next

we must tap holes in the motor's gear case to allow the cover

and encoder mounting plates to be attached using 6-32 screws. We

must also drill and tap (8-32) the motor shaft on the gear side. The

cover plate will need a hole drilled to allow the encoder disk

to be attached to the motor shaft.

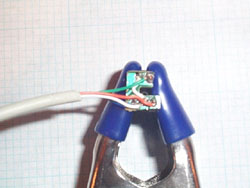

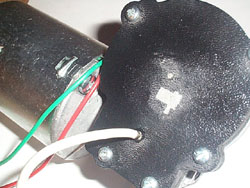

The

mouse cord has four wires, just what we need! I use white

as +5v, green goes to ground (through a resistor!). Orange

& Blue to the sensor outputs. These outputs must

go through transistors before they go to the OOPic. Those

transistors and other components will go on a simple circuit

board which I will talk about later. For now, I just

solder the wires to the sensor like this. (The blue wire is

difficult to see, it's below the white wire.)

Here

are all five sensors soldered to their cables.

Using

the lathe to drill the hole, for the encoder disk, into the

motor shaft.

Tapping

the motor shaft hole with an 8-32 tap.

Cutting

8-32 threads onto the encoder disk shaft.

Test

fit - Screwing the encoder disk into the motor shaft.

Tapping

five holes into the gearbox to allow the cover to be attached

with five 6-32 screws. Note that the correct size holes

are already present on the Dewert motor's gear box!

A

shot showing the cover mount screws in the newly tapped holes.

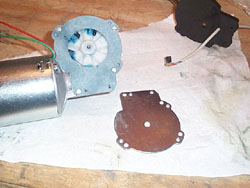

The

Gear and washer have been replaced.

The

gasket is in place and the cover plate and top cover with the

sensor are ready to go.

With

the cover plate in place I screw the encoder disk into position.

I used a drop of super glue when I did this to lock it

at the right spot. I use the sensor to determine the correct

spacing (don't want to screw it in too far, or not far enough!).

The

bottom plate is positioned with the sensor in place around the

encoder disk.

The

top cover is put into position and screwed in place. After

testing to make sure the encoder is working I put some plumber's

epoxy in the opening on the top cover to seal it off.

Here's

a shot of all five motors with encoders attached.

Previous

Entry Top Next

Entry